Specializing IN

|

Column align: middle

|

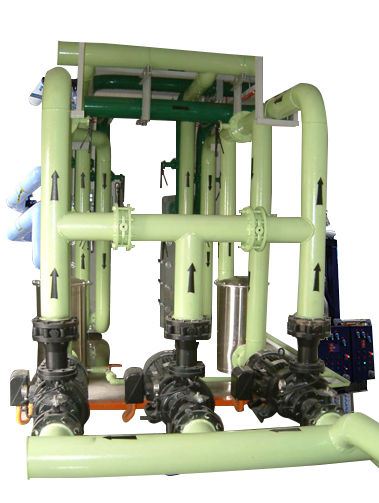

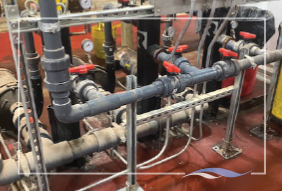

Integrating Safe and RELIABLE PIPING SyStems

The development and maintenance of the piping systems in industrial plants plays an important role in the success of the entire operation. The key is to optimize the systems to use the ideal material, and build or update the route layouts to account for what the pipes is carrying. It might mean taking into account the shortest distance and curves to get the substance processed quickly or it could mean taking into consideration the heat or pressure that will be in the pipe as it carries the substance. Our team has the expertise to assist our customers in creating and maintaining the most efficient and stable piping systems within and outside their plants across vast industries.

|

Types of Systems

|

Vertical Divider

Types of Pipe Materials

|

Vertical Divider

Types of Substances Transporting

|

industries we serve

Safety

Safety is a top priority at KWMI.

We take every step possible to protect your organization, our team and our facilities, using a system of checks and balances to ensure that our safety measures exceed industry standards.

|

Safety protocol we follow on a regular basis include:

|

|

Many of our our team members are certified trainers in their unions. As a result, our tradesmen are always

up-to-date on the latest methods. In addition, all team members are trained on OSHA 30 requirements. We have also partnered with a local safety consulting firm to further enhance our focus on safety standards and procedures. We empower our team members with the knowledge and tools necessary to follow the best safety protocols based on existing guidance and marketplace trends.

up-to-date on the latest methods. In addition, all team members are trained on OSHA 30 requirements. We have also partnered with a local safety consulting firm to further enhance our focus on safety standards and procedures. We empower our team members with the knowledge and tools necessary to follow the best safety protocols based on existing guidance and marketplace trends.